Home > Our Vision

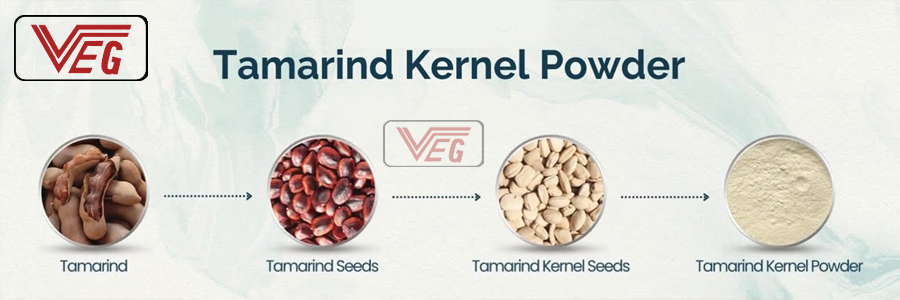

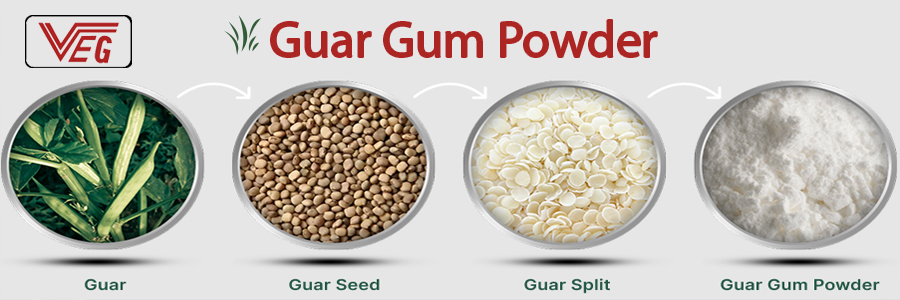

To be the global leader in the manufacturing and supply of premium, sustainably sourced hydrocolloids, specifically Tamarind and Guar Gum powders. We aim to be the most trusted and preferred partner for industries worldwide, recognized for our commitment to quality, innovation, and environmental stewardship.